Description

Circuit breaking power connector solutions like the Quelarc® line give engineers a heavy-duty way to safely make and break 30, 60, and 100 amp circuits up to 600 VAC in harsh industrial environments. Designed for portable and detachable electrical equipment, Quelarc plugs and receptacles combine rugged metal housings, long insulating creepage paths, and compound arc chambers to deliver dependable circuit-breaking performance under load.

Table of Contents

- Quelarc Circuit Breaking Power Connector Overview

- Key Features & Benefits

- Electrical Performance & Ratings

- Mechanical & Environmental Performance

- Materials & Construction

- Typical Applications & Use Cases

- Installation & Safety Best Practices

- Resources & Related Solutions

Quelarc Circuit Breaking Power Connector Overview

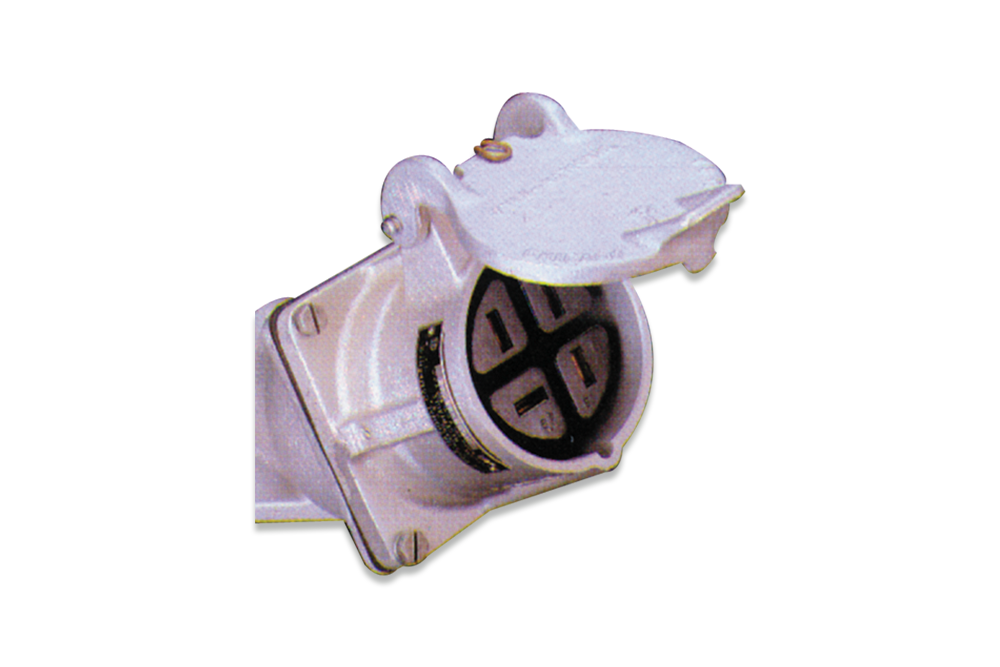

The Quelarc® circuit breaking power connector family is engineered for safe, repeatable power distribution where equipment must be plugged in and disconnected under load. Available in 30 A, 60 A, and 100 A models rated up to 600 VAC and 250 VDC, these cylindrical plugs and ferrous alloy receptacles are built to withstand the most severe operating conditions while maintaining stable electrical performance over long service life. Unlike standard industrial plugs that are not evaluated for switching live current, Quelarc devices integrate a circuit-breaking mechanism that interrupts and cools the arc inside controlled chambers while the plug remains fully engaged with the receptacle housing. This design helps protect personnel, equipment, and upstream protective devices during make-and-break operations in demanding industrial environments.Key Features & Benefits

Quelarc circuit breaking power connector designs combine rugged mechanical construction with multiple layers of electrical protection so portable and detachable loads can be connected safely in the field.- True circuit-breaking design — compound arc chambers confine, stretch, and cool the arc as contacts separate, helping extinguish it before the plug is withdrawn.

- Extra-long insulating creepage paths — molded partitions and barriers between male contacts extend the insulating surface between poles and from pole-to-ground, reducing tracking and arcing in damp or dusty conditions.

- Ground-first, ground-last operation — a dedicated grounding pole or shell ground engages before the power poles and disconnects last, improving personnel safety and system protection.

- Heavy-duty housings — cylindrical aluminum plugs and ferrous alloy receptacles resist impact, abuse, and mechanical strain in harsh industrial environments.

- Flexible couplings — threaded and press-fit (push/pull) coupling options help prevent accidental disengagement due to vibration or cable tension.

- Special polarizations — distinctive keying patterns prevent mismating between different voltage systems or wiring configurations.

- Reversible insert assemblies — available for reverse service applications where the traditional plug/receptacle power flow needs to be reversed.

- Optional flip-type covers — protect receptacle faces from contamination and mechanical damage when not in use.

Electrical Performance & Ratings

Quelarc plugs and receptacles are designed to carry and interrupt medium-current power circuits for both AC and DC systems commonly found in heavy industrial facilities.- Amperage options: 30 A, 60 A, and 100 A models for flexible load sizing.

- Voltage ratings: up to 600 VAC and 250 VDC, depending on configuration and catalog number.

- Poles and wires: 2- to 4-wire options in 3-pole layouts support grounded single- and three-phase systems.

- Circuit-breaking capability: evaluated for making and breaking rated current under load when used within published application limits.

- Insulation system: molded arc chambers and insulating barriers help maintain dielectric integrity in the presence of moisture or conductive dust.

Mechanical & Environmental Performance

The Quelarc product line is built for demanding shop, plant, and outdoor environments where vibration, contamination, and temperature extremes are part of daily operation.- Cable O.D. range: approximately 0.1875 in to 0.625 in, supporting a wide range of industrial cable sizes.

- Mating cycles: typical 100-cycle rating for long-term reliability in high-duty applications.

- Ingress protection: IP67 protection class in properly mated and assembled configurations.

- Operating temperature range: -40 °C to +125 °C for cold-start and elevated-temperature environments.

- Compliance: RoHS and REACH options to support global environmental requirements.

Materials & Construction

Material selection in the Quelarc circuit breaking power connector is optimized for electrical performance, mechanical strength, and long-term durability.- Shell: aluminum plug bodies and ferrous alloy receptacles provide robust impact resistance and rugged environmental performance.

- Contacts: high-conductivity copper contacts support high current with low temperature rise.

- Contact plating: bright-dip finishes for stable conductivity and corrosion resistance.

- Sealing components: rubber elements help maintain IP67 sealing and protect internal components from moisture and dust.

- Hardware and covers: optional flip-type covers and junction box hardware protect contact areas and cable entries.

Typical Applications & Use Cases

Quelarc circuit breaking power connectors are used anywhere portable or detachable equipment must be connected to plant power in harsh or dirty environments.- Portable welders, motors, pumps, compressors, and material-handling equipment.

- Steel mills, foundries, and heavy manufacturing plants with high levels of dust, vibration, and thermal cycling.

- Rail and transit maintenance facilities using portable power drops and shop tools.

- Shipyards, ports, and marine environments that demand rugged connectors with long service life.

- Temporary or modular power distribution for construction projects, process upgrades, or equipment trials.

Installation & Safety Best Practices

Proper installation is critical to realizing the full safety and reliability benefits of Quelarc connectors. The following best practices are typical recommendations for circuit breaking power connector applications:- Follow the connector’s wiring diagram, torque values, and cable range guidelines for each specific catalog number.

- Ensure that the grounding path (via ground pole or shell) is permanently bonded to the equipment grounding system.

- Use compatible junction boxes, gaskets, and conduit fittings to maintain enclosure integrity in wet or dusty locations.

- Verify that voltage, amperage, and number of poles match the intended system and polarization scheme.

- Inspect plugs, receptacles, and junction boxes periodically for mechanical damage, contamination, or worn contacts in high-duty-cycle applications.

- Apply site lockout/tagout procedures when servicing equipment, even when a circuit breaking power connector is used as the local disconnecting means.

Resources & Related Solutions

To support specification, installation, and cross-market design work, engineers can reference the following Quelarc and related resources:- Quelarc catalog & datasheets: detailed dimensional data, wiring configurations, and ordering information are available in the Quelarc catalog PDF linked in the product downloads.

- Additional Industries overview: see how Quelarc fits into a broader portfolio of harsh-environment power solutions on the Additional Industries market page.

- Heavy Equipment applications: explore system-level connector solutions for mobile machinery on the Heavy Equipment market page.

- UL connector certification overview (external): for more information on UL 1682 and switch-rated pin-and-sleeve connector evaluations, visit UL’s connector certification services page.

Features & Benefits

30/60/100 AMP, 250 VDC/600 VAC

Switch Blade Contacts

Grounding Shell through extra first mate last break pole

Special polarity for different voltage

Available with 2 wire up to 4 wire designs

Plugs/Receptacles available for threaded or push/pull mating

Utilize ground contact or ground through shell design

Junction box options include angle or straight designs

Reversible insert assemblies available for reverse service applications

Receptacles come with optional flip type cover

Specifications

Electrical

Voltage

600V AC

Current Rating

200A

Number of contacts

2 to 4

Certifications

UL

Mechanical

Cable O.D.

.1875-.625

Mating cycles

100

Material

Contact plating

Bright dip

Contacts

Copper

Sealing components

Rubber

Shell

Aluminum

Environmental

Temperature range

-40°/+125°C

Protection class

IP67

RoHS

Yes, optional

REACH

Yes, optional

Connectors to fit your industry requirements by design

TS1 Series | High Current eMobility Power Connector

eMobility, High Current, HV Connector, Shielded, Single-Pole

Floating Mate Connector Series | Floating Blind Mate Connector

Energy Storage, Floating Mate, Blind-Mate, Power Connector

Amphe-PV H4 Plus™ Cable Connector | Solar Connector

Panel, Power, Solar Connector

Liquid Cooling Systems | Reliable Quick Disconnect Connectors

High-Performance Thermal Management for data centers, EVs & ESS. Discover UQD & UQDB quick disconnects for high-efficiency thermal management.

Connect with Our Team

Amphenol Industrial's product lines consist of rectangular, standard miniature, fiber optic, EMI/EMP filter, and a variety of special application connectors.

Online Quote

Support