New Series Added for Seamless, OCP-Aligned Integration

Discover how OCP-compliant liquid cooling quick disconnects can transform your cooling strategy.

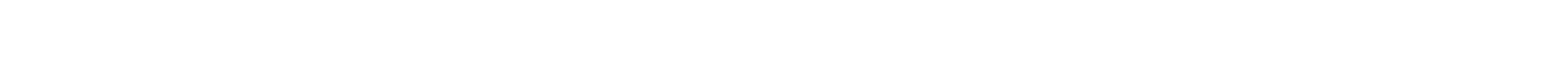

OCP-compliant liquid cooling quick disconnects from Amphenol Industrial Operations now span a full, interoperable ecosystem for modern AI and data center thermal loops. With the addition of BMQC, LQC, and MQD—alongside UQD and UQDB—buyers and engineering teams can standardize on one portfolio of OCP-compliant liquid cooling quick disconnects across rack manifolds, CDUs, cold plates, and rear-door heat exchangers (RDHx) to accelerate installs, simplify service, and protect uptime.

Table of Contents

Why This Expansion Matters for AI-Scale Thermal Architectures

As rack power densities rise, liquid becomes the reliable path to thermal headroom. Standardizing quick disconnects across the loop shortens integration timelines and reduces onsite variability. Amphenol Industrial Operations (AIO) now provides a single-source, OCP-aligned family with shared design intent—clear tactile engagement, low-spill serviceability, and consistent sealing performance—so operations teams can scale confidently without piecing together mixed-spec components.

Portfolio at a Glance: One Ecosystem, Multiple Use Cases

The family now comprises five series—BMQC, LQC, MQD, UQD, and UQDB—giving specifiers flexibility to match connector characteristics to each zone of the cooling loop. Whether the requirement is robust duty on facility lines or compact geometry inside high-density racks, the portfolio covers the range while maintaining familiar assembly practices and service workflows.

BMQC: High-Duty Performance for Facility and Rack Loops

Best for: Manifold trunks, facility-side loops, and high-cycle service environments. BMQC emphasizes mechanical robustness and a smooth mate/demate feel to support fast service intervals. Coding options promote line-side accuracy, helping reduce cross-connection errors in environments with multiple fluids or redundant paths. The result is a durable interface designed to sustain repeatable performance through maintenance cycles.

LQC: Compact Footprint for Dense Deployments

Best for: Tight envelopes and high-density rack architectures. LQC delivers a space-savvy profile that helps preserve airflow paths and service clearances around cable management and IT gear. Its service-friendly design supports rapid changeouts, while sealing elements are optimized for consistent, repeatable performance—key for minimizing unplanned downtime during module swaps or cold plate maintenance.

MQD: Versatile, Installer-Friendly Configurations

Best for: Mixed interfaces around cold plates and CDUs. MQD offers flexible configurations to accommodate different port orientations and line routings, reducing the need for ad hoc adapters. Clear tactile engagement helps technicians confirm “positive lock” in low-visibility spaces, and streamlined assembly steps reduce total time on site.

UQD & UQDB: Proven Baseline for Rack-Level Liquid Loops

Best for: Rack interiors and standard plate connections. UQD and UQDB—released earlier this year—established AIO’s baseline for service-first design: confident mating, controlled disconnect behavior, and consistent sealing to keep loops clean during maintenance events. Together with BMQC, LQC, and MQD, they create a coherent set that maps cleanly to the varying mechanical and service constraints in AI racks.

Benefits of Standardizing on One OCP-Aligned Family

With OCP-compliant liquid cooling quick disconnects, the focus is on delivering consistent performance across all applications and environments.

Interoperability: A single portfolio reduces vendor fragmentation and streamlines spares, training, and documentation. Serviceability: Smooth mate/demate, low-spill behavior, and coding options shorten maintenance windows while reducing rework. System Focus: Choices tuned for manifolds, CDUs, cold plates, and RDHx, so engineers can specify by application rather than compromise on a one-size-fits-all connector. Operational Continuity: Repeatable sealing performance and tactile feedback support predictable MOPs/SOPs in live data halls. Global Support: Access to engineering collaboration and samples helps teams validate configurations and accelerate qualification.

Utilizing OCP-compliant liquid cooling quick disconnects provides clear advantages in terms of system integration and maintenance efficiency.

OCP-Compliant Liquid Cooling Quick Disconnects in Practice

Implementing OCP-compliant liquid cooling quick disconnects can drastically enhance the serviceability and interoperability of your cooling solutions.

The design of OCP-compliant liquid cooling quick disconnects ensures a minimal risk of leaks, promoting a safer operating environment.

In typical AI rack deployments, facility loops feed CDUs, which drive conditioned coolant to rack manifolds and cold plates. BMQC can anchor higher-duty sections that see the most handling and mechanical stress. LQC fits constrained rack interiors where every millimeter matters. MQD bridges varied interfaces with flexible form factors, while UQD/UQDB provide a proven baseline for common rack connections. Selecting from one family reduces interface mismatches, simplifies kitting, and shortens installation and commissioning schedules.

OCP-compliant liquid cooling quick disconnects are essential for optimizing the operational efficiency of any data center.

For the latest in cooling technology, OCP-compliant liquid cooling quick disconnects lead the market with their exceptional performance.

Qualification, Documentation, and Next Steps

By utilizing OCP-compliant liquid cooling quick disconnects, teams ensure that their installations are not only efficient but also align with the OCP standards.

To speed evaluation, AIO supports early design reviews, guided sample kits, and application notes covering recommended torque targets, seal materials, and cleaning/maintenance guidelines. Distributors benefit from a unified message and parts strategy, while OEMs gain confidence that field teams will experience consistent tactile engagement and sealing behavior across the entire loop.

Ready to align on specs or build a shortlist for your rack architecture? Our team can help map the right connector to your flow rates, delta-T targets, and service models.

Stay up-to-date with all Amphenol Industrial News

APC Series Expansion: Enhanced Designs for Modern Industrial Systems

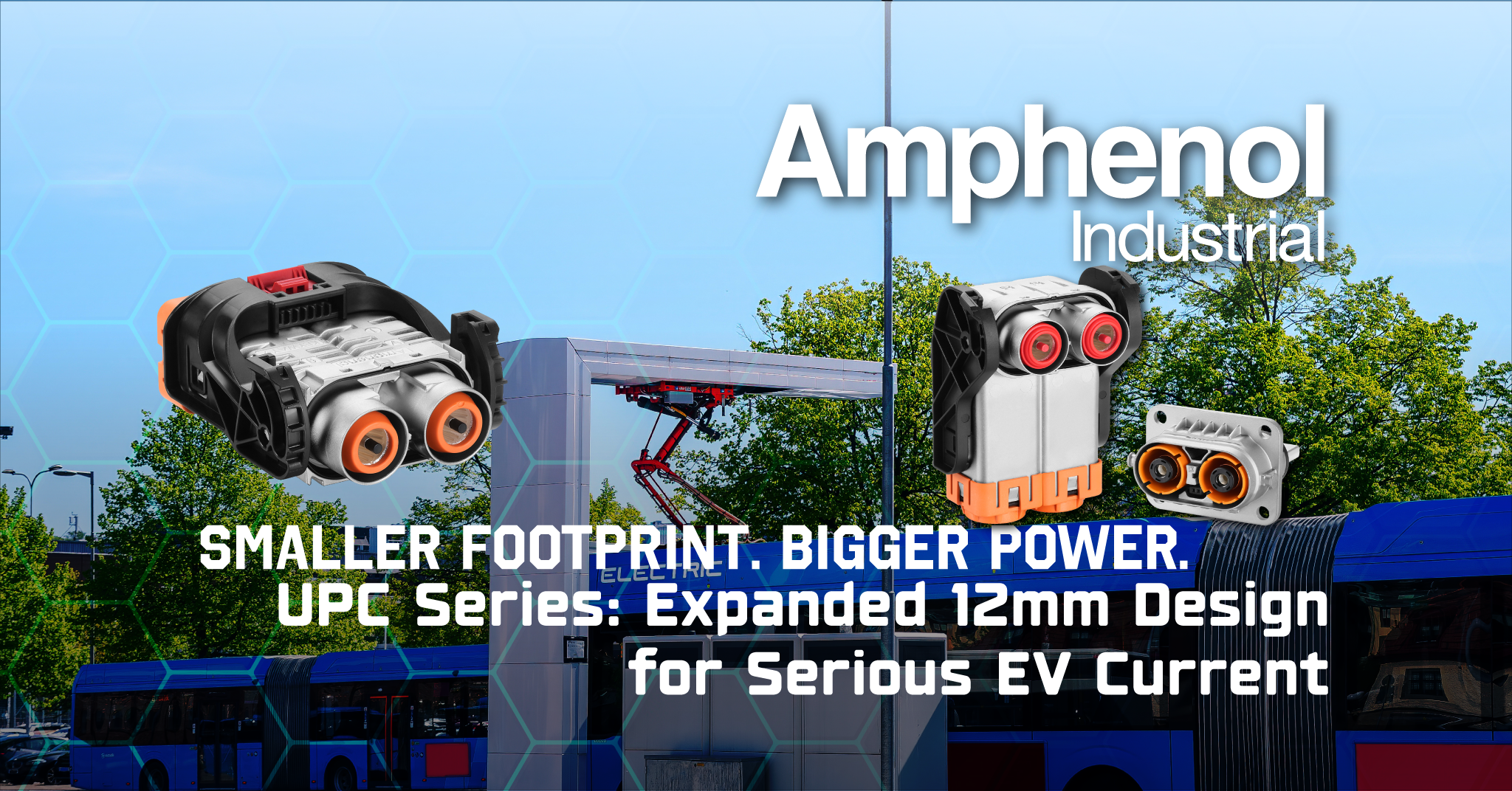

UPC 12mm Connector Expansion Delivers Powerful, Compact High-Voltage Performance

SurLok Plus 10.3mm Straight Plug: Powerful 1500V DC Expansion

Connect with Our Team

Amphenol Industrial's product lines consist of rectangular, standard miniature, fiber optic, EMI/EMP filter, and a variety of special application connectors.