Description

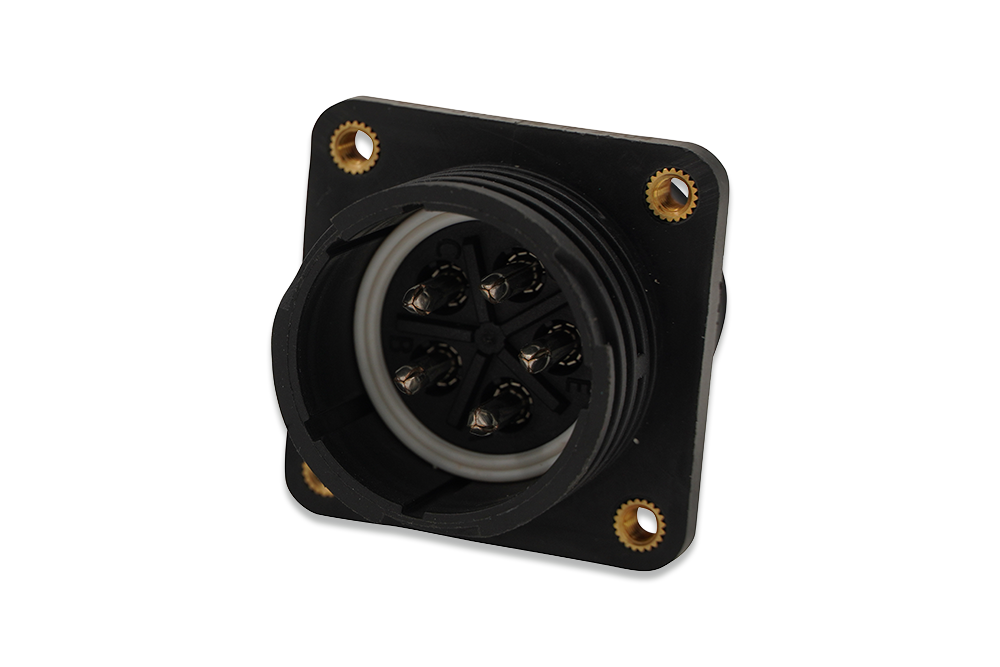

APC Series connector overview

APC Series connector key specifications

Ingress protection: IP67 when mated (see IEC 60529 IP overview)

Operating temperature: −40 °C to +105 °C

Mating durability: up to 500 cycles (application dependent)

Electrical (typical by contact size): size 16 ≈ 13 A; size 12 ≈ 23 A; size 10 ≈ 30 A; APC Mini signal ≈ 7.5 A at 250 V AC

Materials: plastic shell with UV (F1) and UL 94 V-0 performance

Coupling options: triple-start ACME thread (Standard), double-start thread (Mate), two-way bayonet (Mini)

APC Series connector variants & coupling

APC Standard: triple-start ACME thread for fast engagement and vibration resistance.

APC Mini: compact two-way bayonet for dense panels and quick field service.

APC Power: elevated current capability in a lightweight plastic shell for power-dense subsystems.

APC Mate: double-start thread option for a preferred engagement feel without sacrificing sealing.

Because these variants share a common design philosophy and accessory ecosystem, engineering teams can qualify one family and deploy the right envelope and coupling style per subsystem.

How APC Series connector differs from typical CPC

- Faster mating: triple-start ACME or bayonet vs. common single-start threads.

- Lighter weight: plastic shell with UV/UL performance vs. heavier metal bodies.

- Unified family: power, signal, and hybrid layouts under one accessory ecosystem.

- Serviceability: tactile lock-in, clear keying, and standard crimp tooling for repeatable installs.

Design versatility and accessories

Engineers can specify power, signal, or hybrid inserts to consolidate multiple connectors into a single validated platform. Clear polarization and mechanical keying help prevent mis-mates, while alternate insert rotations support error-proofing on crowded panels. Panel-mount and cable-mount variants, straight and 90-degree strain-relief backshells, and protective caps give packaging flexibility. For adjacent high-current DC needs in the same rack or cabinet, see SurLok Plus as a complementary solution.

Installation and serviceability

Fast-mating mechanisms provide tactile feedback at full engagement, reducing the likelihood of partial seating and rework. Optional backshells, clamps, boots, and protective caps maintain strain relief and protect sealing surfaces during shipping and maintenance. A straightforward crimp-and-assemble process—supported by size-matched insertion and extraction tools—helps technicians meet IPC/WHMA-A-620 workmanship expectations on the line and in the field.

Applications and use cases

APC Standard is a strong default for mixed power and signal where robust threading and fast assembly are required. APC Mini shines in instruments, hand tools, and compact control boxes where density matters and quick service is preferred. APC Power suits higher-load subsystems in heavy equipment, transportation, power distribution, and energy storage, where stable temperature rise and rugged mechanical stability are essential. Typical sites include control cabinets, motors, transformers, process instrumentation, HVAC blowers and controls, lighting and signage, materials handling, rail and transit, and outdoor enclosures exposed to dust, moisture, and sunlight.

Resources and next steps

Define sealing targets with the IEC 60529 IP overview. Need drawings, samples, configuration help, or quotes? Visit Sales Support. To pair APC with high-current DC terminations, explore SurLok Plus.

Features & Benefits

Specifications

Electrical

Mechanical

Material

Environmental

Connectors to fit your industry requirements by design

Amphe-PV H4 Plus™ Cable Connector | Solar Connector

Liquid Cooling Systems | Reliable Quick Disconnect Connectors

GuardXcel™ Cable Glands | Secure Solutions for Engineers

H4 PRO™ PV Connector | The Pinnacle of Solar Connector Types

Connect with Our Team

Amphenol Industrial's product lines consist of rectangular, standard miniature, fiber optic, EMI/EMP filter, and a variety of special application connectors.